Browse Items (120 total)

- Tags: Westinghouse Electric Corporation

Capital Cogeneration's Westinghouse 501D5 Gas Turbines

Dow Chemical Company's Westinghouse 501D5 Gas Turbines

We Are Building a New Image in Concordville

Westinghouse Electric Combustion Turbine Systems Division

Westinghouse Electric Combustion Turbine Operations Mug

Bellingham Energy Center

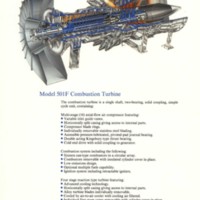

Westinghouse 501F Combustion Turbine

Westinghouse 501F Combustion Turbine Advertisement

Value Plus: Introducing the Westinghouse 501F 145-MW Advanced Design Combustion Turbine System

First Westinghouse-Manufactured 501F Heads to Korea: Shipment Culminates of 24 Months of Work

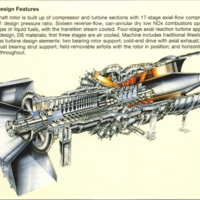

501G Design Features

First Westinghouse 501G Being Shipped from Hamilton Works

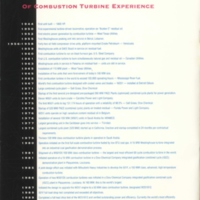

Westinghouse: A Proud History of Combustion Turbine Experience

Tags: blast-furnace gas; Bunker C; Canadian Utilities; coal gas; coal gasification; combustion turbines; cooled blades; cooled vanes; Creole Petroleum Corporation; DAEE Brazil; Departamento de Águas e Energia Elétrica; Detroit Edison Company; Dow Chemical Company; electric power generation; Fiat Automobiles; Florida Power and Light Company; IGCC; integrated gasification combined cycle; locomotives; Mississippi River Fuel Corporation; Mitsubishi Heavy Industries; natural gas; oil field compressors; PACE; peaking units; Power at Combined Efficiency; power plants; railroads; residual fuel; residual oil; Salt Grass Combined-Cycle Plant; Saudi Arabian Oil Company; Saudi Aramco; trains; U.S. Steel; U.S. Steel Company; United States Steel Corporation; vanadium; W251; W251B12; W501; W501D5; W501F; West Texas Utilities; Westinghouse 251; Westinghouse 251B12; Westinghouse 501; Westinghouse 501D5; Westinghouse 501F; Westinghouse Electric Corporation

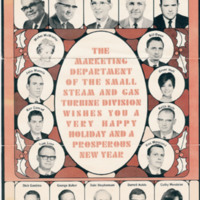

Westinghouse Electric Small Steam and Gas Turbine Division Christmas Card

Tags: Al Becker; Bill Owen; Cathy Wendeler; Christmas; Dale Stephenson; Darrell Aulds; Dick Gaskins; Don Jones; George Baker; Greer Holt; holidays; John Coffen; John Magee; John Munnis; Keith Wein; Ken Conrad; Mable McMaster; New Year's Eve; Ron Moreland; Small Steam and Gas Turbine Division; SSgt; Ted Anthony; Tom Lane; Westinghouse Electric Corporation